Rockwool Composite Panels

Asia Cuanon® Rockwool Composite Panels, also name as vertical thread rockwool combination panels, which are made by sizing agents as surface materials and hydrophobic vertical thread rockwool mouldings as filling. Binding performance of rockwool is enhanced via size agents, also has such advantages as non-inflammable, low water absorption and high strength, is the most ideal fire proofing grade A insulation.

Executive standards: DGTJ08-2126-2013 “Application technology code of rock wool external thermal insulation systems”

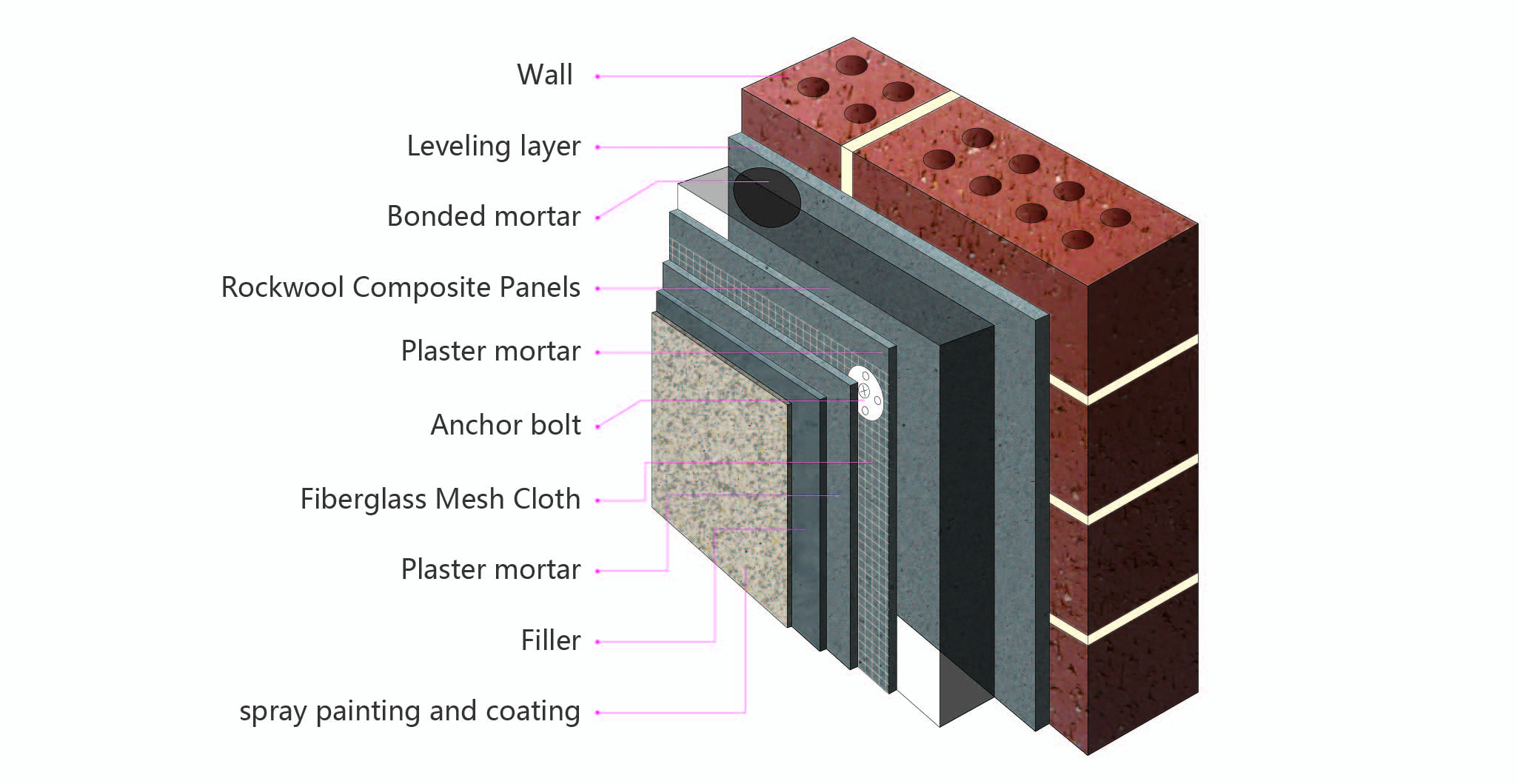

System structure

Advantages

1.Turn transverse to vertical (changing the direction of rock wool fibers, changing the transverse filament of traditional rock wool pane into the vertical filament of rock wool composite panel).

(1)Avoid slab joints cracking

(2)Avoid panel shedding

(3)Avoid panel warping or transforming

(4)Avoiding condensation on walls

2.Turn bare to enfolded (changing the bareness of traditional rock wool, compounding a flexible waterproof mortar layer on the surface of rock wool).

(1)Increase the strength of the panel surface

(2)Improve construction quality

(3)No special anchor bolt for rock wool is needed.

(4)Improve the hydrophobicity of panel surface

(5)Protect the construction environment and avoid skin irritation

(6)Make the specification of panel accurate

(7)Shorten construction period

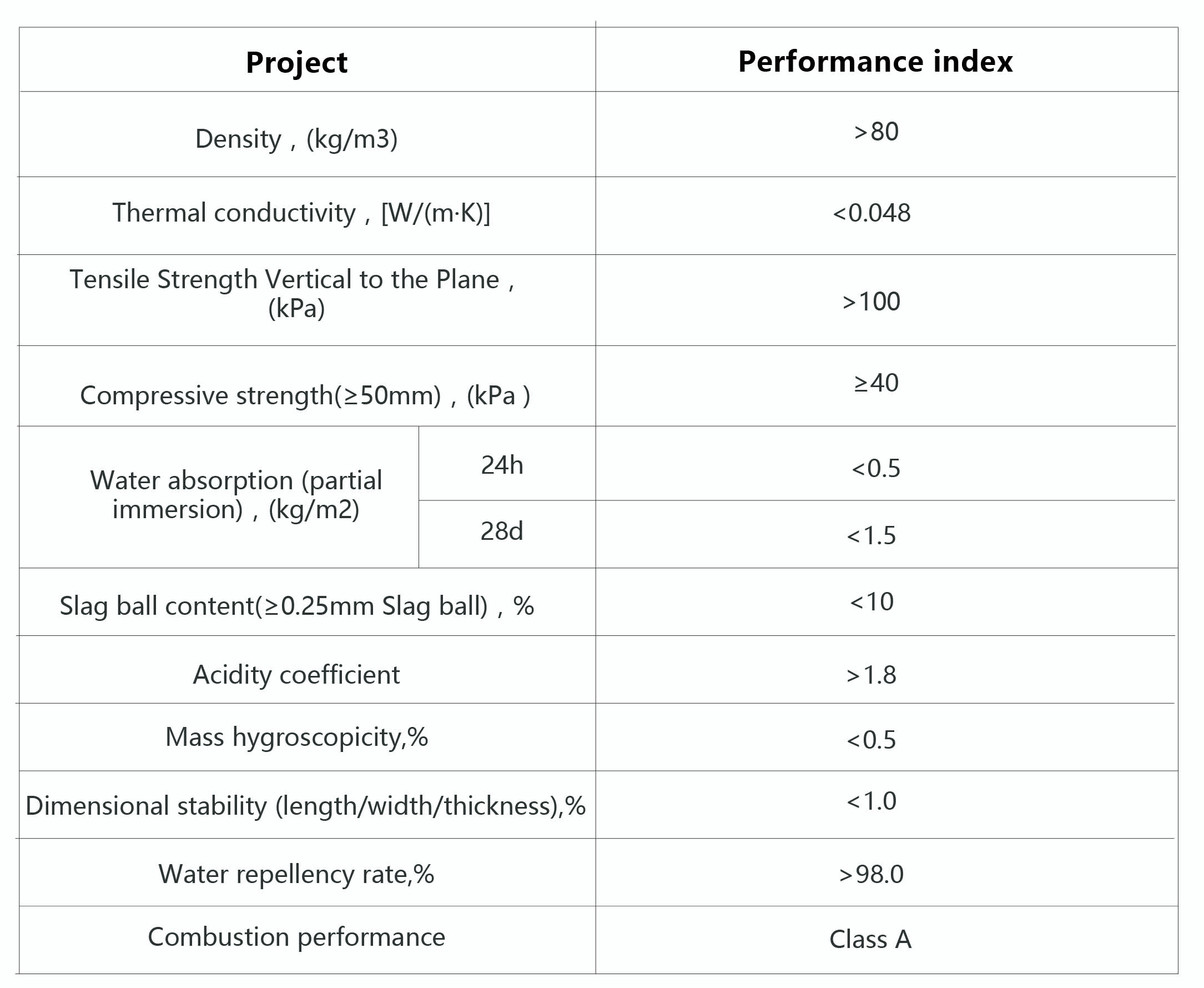

Performance index of rock wool belt technology

Performance index of Rockwool Composite Panels